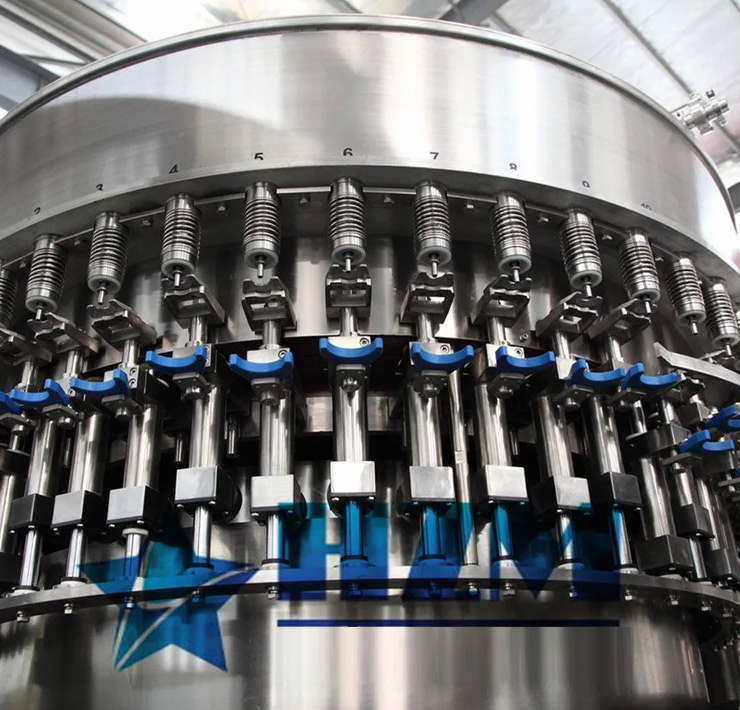

Mizutech India has attained a reputed place in the industry for providing a quality assured range of Water Filling Machine, Soda Filling Machines, Juice Filling Machines. We are offering you the complete range of 30BPM, 60BPM, 90BPM, 120BPM and also customized as per customer need and requirement.

Saves Times: Time can be saved by using a CSD filling machine to swiftly and efficiently fill bottles instead of doing it by hand.

Accuracy in Filling : You won’t ever experience an Overfilling or Underfilling issue again since a CSD filling machine is designed to supply the proper level of CO2 for each Drink .

Less Waste Production: Since CSD filling machines will only release the right amount of CO2 for each drink, there is less waste produced and a lower likelihood of a mess.

Easy Maintenance: It is easy and simple to clean and maintain. When you are finished using it, simply wash the machine with Warm Water and Soap.

A Carbonator pump is a device that infuses Carbon Dioxide Gas under high pressure into a liquid, thus creating bubbles that make the liquid effervescent.

The carbonator consists of a Carbonation Tank, Piston Pump, and the Electrical Panel. The carbonator works on the film flow principle. A very fine film of liquid is created and allowed to flow over specially contoured film plates.

In the production of a carbonated beverage, the concentrated flavoring (beverage base) is combined with a nutritive or nonnutritive sweetener and water to form a syrup. The syrup is mixed with a proportioned quantity of carbonated water followed by filling and sealing the beverage in a container.

Carbonation is a solution of carbon dioxide gas in water. The carbon dioxide is generally kept in the water through pressure (either in a bottle or in a natural spring), and will slowly release once that pressure is relieved, forming bubbles of carbon dioxide gas.

The Carbonation process for Soft Drinks involves adding carbon dioxide gas to a liquid to give it a tangy taste, sparkle, and to prevent spoilage. The process can be done in a few ways like below :

1-In-line Carbonation : A cold product is sprayed into a pressure vessel filled with carbon dioxide , increasing the surface area and saturating the product with CO2. The carbonated product is the stored in the pressure vessel until it’s ready to be filled into bottles or cans .

2- Injecting Gas into a pressure-sealed Vessel: The gas is injected continuously into the liquid flow through a Venturi, which increase mixing efficiency and carbonation levels. The beverage is then collected in pressurized tanks or directly in bottles .

3- Carbonation inside the Tank : The product is carbonated inside the tank, which provides a large area of contact between the product an d CO2 allowing the liquid to absorb more CO2 .

Other aspect of the carbonation process is Chilling the liquid, Increasing the pressure, Lowering the temperature, and Using Dry Ice or liquid carbon dioxide.

Carbonation is a process wherein pressurized CO2 is passed through water, producing carbonic acid along with dissolved CO2 gas. Most carbonated drinks, which are approximately 94% water, have pH around 2.5 to 3.5, and hence are highly acidic.

A typical Carbonated Soft Drink contains approximately 3-4 volumes (6-8 g/L) CO2..

Mr. Dilip Kumar Suman

Mobile No- 9311611741

info@mizutechindia.com

Mr. Abhishek Ranjan

(Marketing Director)

Mobile No: 9311611744

sales@mizutechindia.com

Shivanand yadav

(Project Head)

Mobile No: 9311611743

| Application | For Oil, Juice Any other Liquid |

|---|---|

| Filling Volume (ml) | 100ml -10000ml |

| Head/Nozzle | 2 Head ,4Head ,6 Head |

| Machine Frame MOC | SS 304 Square Pipe |

| Machine Base Plate MOC | SMild Steel With Redoxide Coating |

| Machine Casing MOC | SS 304 |

| Door | Front With Interlock |

| Syringe | MOC SS 304 |

| Syringe Holding Assembly | Mild Steel With Redoxide Coating |

| Assembly Enclosure | SS 304 |

| Piston Rod | SS 304 |

| Piston Ring | Teflon |

| Nozzle | SS 304 |

| Nozzle Type | Antidrip, Diving Type |

| Hose | Food Grade, Silicon Braided |

| Max Temp of Filling | 100°C |

| Volume Adjustment | Escentric Block |

| Stopper Cylinder | 3 no, Pneumatic Sensor Based |

| Bottle Block Sensor | Defuse Type Photo sensor |

| Conveyor | SS 304 |

| Panel Details | Push Button Operated |

| Feed Tank Hi & Low Level Sensor & 1 HP Feed Pump Provision | |

| CIP Provision | Tray Type |

| Pneumatic Details | 2-4 CFM @ 6-8 Bar |

| Electrical Details | PConveyor – 0.5 HP With Gearbox |

| 2KW 3 Phase, 415-440 V AC, 50 Hz |

Stainless Steel Tanks are made by food grade material which maintains the quality of water in natural form. As well light cannot pass on Stainless Steel Tanks so free from chemical reactions and water contamination. Compared with other tanks.Highly durable with free from maintenance cost and recyclable in nature thus the overall cost is tremendously low in long run which justifies the value of investment.

We have the capacity to fabricate your storage tank with any capacity and any shape.

With adjusting guide for packaging of Different size & packing of Bottles

| Model | Sealer | Shrink Tunnel |

|---|---|---|

| Voltage(VHZ) | 300/50-3 Phase | 380/50-3phase |

| Power Consumption(KW) | 15 | 21 |

| Packing Speed (pcs/min | 0-12 | 0-10 |

| Max Packing Dimension | 500x290x380 | 1450x550x400 |

| Max Sealing Length | 650 | ———— |

| Height of conveyor | 800-50(Adj.) | ———— |

| Working Air Pressure | 6/Kg/M | ———— |

| Dimension(LXWxH) | 1370x920x1800 | 2550x850x1500 |

| Conveyor Loading (KG) | ———— | 40 |

| Heating Time(Minutes) | ———— | 10 |

| Cooling Time(Minutes) | ———— | 15 |

| Cooling Time (Minutes) | ———— | 15 |

| Weight(Kg) | 80 | 250 |

| Capacity | 60-120 BPM |

| Size of bottle | 0.2l to 2.0 L bottle with change part for each |

| Air Required | 100 ltr per minute at 5kg/cm2 pressure |

| Conveyor working height | 1050+-50 mm |

| Size (L X B X H) | 1700x1200x800 mm |

| Electric Load | 7.5 KW |

Heating system controlled with PID Controllers

Batch printing machines, marking machines, and date printing machines are used in the following applications:

| PART NO. | DESCRIPTION | QTY |

|---|---|---|

| WIE-0400 | Photo Electric Sensor | 1 Nos |

| 500-00-36-581 | 4w ip67 Cab, MTG, Plug | 1 Nos |

| With-0400-00 | Encoder Mounting Bracket | 1 Nos |

| WIE-0400-121 | 5000 PPR Shaft encoder | 1 Nos |

| W521-D | Ink,Black,750 ml | 2 Nos |

| W816-D | Make-up,750 ml | 2 Nos |

| W912-Q | Cleaning Solution, 1 Ltr | 2 Nos |

| VJIb0390 | W630 machine sand & Printer head stand | 1 Nos |

| WIE-0400-42 | 3 Pin top Plug | 1 Nos |

| VJ-0400-262 | Sensor Bracket for Calypso | 1 Nos |

| WIE-0400-006 | 3 Way din plug | 1 Nos |

Water is a scarce resource and due to Urbanization and Globalization water usage will increase in the coming years. Industries like power, oil, and gas, pharmaceuticals, and chemicals generate a large volume of wastewater which contains solid waste, organic waste, toxic and non-toxic chemicals which further affects the environment. In fact, many government and industries have come up with initiatives to reduce water waste by installing ZLD, which in turn will reduce water wastage, and help them attain a sustainable environment.

The key driver for zero liquid discharge is a growing concern about the impact of wastewater discharge on the environment. Such concern is resulting in increased regulation and limitation of wastewater discharges. Organizations in India are targeting ZLD for their waste because they can sell the solids that are produced or reuse as a part of the industrial process. For example, salt is the by-product we get at the last stage of ZLD. This salt can be used in the textile process.

Zero liquid discharge is an advanced water treatment process which purifies and recycles the wastewater at the end of the industrial process with zero liquid waste at the end. Zero liquid discharge at Mizutech India is achieved in the most energy efficient method as it saves around 80% of the energy compared to the conventional ZLD techniques used by other companies. The reason why we are so efficient in this process is our patented polymeric film technology which we are using in Mechanical vapour recompression evaporator (MVRE).

Features of ZLD system areMVRE is an energy recovery evaporator which compresses a low-pressure vapour and produces a low volume of vapour with high pressure and temperature. In MVRE influent is heated with steam and the vapour produced are compressed and sent to a heat exchanger where it gets condensed and we get pure water at the outlet. Generally, MVRE is used before MEE to reduce the TDS concentration of influent. This system is available in polymeric film technology. After RO effluent is fed into MVRE to remove high volatile compounds which were not removed in the previous process. In this process water recovered is approximately 80%.

In MEE sequences of vessels are used. Here water is boiled in the vessels, each held at a lower pressure than the last, because the boiling temperature of the water decreases as pressure decreases the vapour boiled off in one vessel can be used to heat the next, and only the first vessel (at the highest pressure) requires an external source of heat. Effluent fed into MEE is of a kind which has very high TDS. Water recovery in this process is around 95%.

Effluent is generated in many manufacturing industries like textile, pharmaceuticals and chemicals, tanneries etc. Contaminated water cannot be released without treatment as it contains toxic and non-toxic chemicals. Releasing it may cause contamination of the existing pure water and will affect the environment. As a result ETP’s are installed in most manufacturing industries.

The Effluent treatment plants (ETP) are used for the removal of high amounts of organic compounds, debris, dirt, grit, pollution, toxic, non-toxic materials and polymers etc. from industrial effluent. The ETP plants use evaporation and drying methods and other auxiliary techniques such as centrifuging, filtration, incineration for chemical processing and effluent treatment.

The addition of the above chemicals by efficient rapid mixing facilitates homogeneous combination of flocculates to produce micro flocs.

Packaged Sewage Treatment Plant (PSTP) is housed in specially designed and highly durable FRP tank. These tanks are compact which can be utilized in a decentralized manner at any location, either it’s underground or above the ground.

The Packaged STP is designed to bring the treated sewage parameters (BOD, COD, TSS, TN etc.) below the permissible limit which is stipulated by the Pollution Control Board. MBBR technology is used in this system.

PROCESS DESCRIPTION OF PACKAGE STPThe first stage of PSTP is an oxygen-depleted anaerobic zone in which the solids in raw sewage gets settled while allowing the scum to float on the surface. It is a zone in which the settled sludge is stabilized by anaerobic digestion.

The sewage then enters the anoxic zone in which denitrification of the wastewater stream is accomplished by returning the activated sludge from the final sedimentation zone to the anoxic zone; wherein dissolved oxygen levels are maintained approximately as 0.2 to 0.5 mg/l. In the denitrification process, anoxic microbes break down to the existing nitrates, this results in the release of inert nitrogen gas into the atmosphere.

The sewage from solid separation zone flows into the aeration zone. Air is diffused with the help of air blowers which encourages the growth of bacteria cultures in and around the floating plastic media added in the aeration zone. The MBBR media provides the extended surface area for the growth of microorganisms.

The next step of treatment involves the sedimentation zone where organic waste is settled. The settled waste in the bottom of the tank is pumped back to the anoxic zone as a return sludge, which is done to ensure that the quality of effluent must pass the stipulated sewage parameters.

The secondary treated sewage is then passed through the Pressure Sand Filter and Activated Carbon Filter for the removal of suspended solids (TSS), colour, and odour. The treated water is then disinfected using sodium hypochlorite before it is reused.

| Key Points | MBBR FRP-PSTP | MS-EP / RCC Conventional STP |

|---|---|---|

| Performance | Decomposition of organic waste is consistent throughout the year | Seasonal variation is observed |

| Monitoring of MLSS & F/M Ratio | Required | Not Required |

| Sludge Removal | Once in 18-24 months | Once in a month |

| Chemicals & Equipment for Sludge Dewatering and Treatment | Required | Once in a month |

| Skilled Supervision | Not Required | Required |

| O & M Cost | 70% reduction compared to conventional STPs | Much higher |

| Tank Maintenance | Leak & rust proof. No root integration & fungal growth | Prone to leak & rust, root integration & fungal growth |

| Tank Maintenance and Durability | Maintenance free and much more durable | Requires frequent maintenance. Much lower durability |

| Installation Lead Time | Within 7 to 10 days | Much higher |

| Upgradation and Relocation | Possible | Not possible |

| SR. NO. | PRODUCTS | CAPACITY RANGE |

|---|---|---|

| 1 | FRP Package Sewage Treatment Plant (ENVI Model) | 2 KLD to 500 KLD |

| 2 | FRP Anaerobic Septic Tank (FAST Model) | 10 KL to 150 KL |

| 3 | FRP Waste Water Equalization / Collection Tank (FET Model) | 10 KL to 150 KL |

| 4 | FRP Water Storage Tank (FWST Model) | 10 KL to 150 KL |

| 5 | FRP Fir Fighting Water Storage Tank (FFST Model) | 10 KL to 150 KL |

Sewage is the waste generated from residential, institutional, commercial and industrial establishments. STP plant treats the sewage to make it fit for safe disposal, agricultural use or domestic use in toilets etc. Sewage usually contains a high quantity of organic and inorganic wastes. It is essential to treat sewage before it enters into any water body. If sewage, is allowed to enter the water sources without treatment, it will contaminate them; which is why it is essential to treat sewage properly before letting it into rivers or any other sources of water.

Areas in a STP PlantIn Primary treatment, wastewater is fed to a screen to remove all large objects that are suspended in the water. After this, the water gets into a Grit chamber where the grit is removed. Grit includes sand, gravel, eggshells, bone chips, seeds, and other materials. Grit removal is necessary to reduce heavy deposits in aeration tanks, digester, channels, and conduits. The next step consists of primary settling tanks. These tanks are usually large in size and the solids settle down due to gravity and are removed as sludge from the bottom. Meanwhile, the oil floats on the surface and is skimmed off. 50-60% of the suspended solids get removed and a 30-40% reduction of the five-day biological oxygen demand can be expected.

Secondary TreatmentSecondary treatment is the second stage of wastewater treatment. In primary treatment, suspended solids, colloidal particles, oil, and grease are removed. Then second biological treatment is done on the wastewater to remove the organic matter present.

This treatment is performed by indigenous and aquatic micro-organisms like bacteria and protozoa which

consume biodegradable soluble contaminants like sugar, fat, detergent, and food waste. These processes are

sensitive to temperature and with an increase in temperature rate of biological reactions increases.

Secondary treatment is divided into two different treatment processes:

Tertiary treatment is the third stage of the wastewater treatment and is also known as an advanced treatment. Tertiary treatment removes the load of nitrogen and phosphorus present in the water. It includes processes like filtration, ion exchange, activated carbon adsorption, electrodialysis, nitrification, and denitrification. Treatment options in tertiary treatment depend upon the characteristics of effluent after secondary treatment and what kind of water is needed at the end of the treatment. For example, if we need potable water then filtration and disinfectionare implemented to process wastewater.

Demineralisation is the Process of removing the mineral salts from water by ion-exchange. Impurities that remains dissolved in water dissociate to form positive and negative charged particles known as ions. These impurities or compounds are called electrolytes. Generally, all natural water has electrolytes in varying concentrations. An ion-exchange vessel holds ion-exchange resin of the required type through which water is allowed to pass. The selective ions in the water are exchanged with ions or radicals loosely held by the resin. In this way, the water is passed through several vessels or a mixed bed vessel so that both positive and negative ions are removed and water is demineralised.

DEMINERALISATION PLANT COMPRISES OFDemineraliser plants are comprises of Mild Steel /SS / FRP Pressure Vessel, Frontal piping wok with manual / Automatic multi port valve butterfly valve / conventional valves for easy operation and control. Available from 100 Liters/hr. to 50000 Liters/hr.

Hard water is frequently unsuitable for many industrial and domestic purpose. When water is referred to as ‘Hard’ it simply means, that it contains excess of calcium (Ca) and magnesium (Mg) Ions than normal water. Carbonate hardness is known as temporary hardness and non-carbonate hardness is known as permanent hardness. The degree of hardness of the water increases, when more calcium and magnesium ions are dissolves. These ions have their origins in limestone sediments and also from carbon dioxide which is present in all waters exposed to the atmosphere and especially in ground water. The easiest way to soft the hard water is through Ion exchange process.

HASSLES OF HARDNESS :-Softening is the ion exchange process, it is done through resin, the most common and probably the easiest method of removing hardness (that is calcium and magnesium) from water and suitable for utility purpose. As the name implies ion exchange is a process in which undesirable ions are exchanged for more desirable ions. The softening process consists of passing raw water containing hardness through a bed of cation resin in sodium form. The hardness ions Ca & Mg are taken up by resin and in exchange, the sodium ions are relinquished from the resin. This is called the service cycle, where the hard water is being softened.

CHEMICAL REACTION DURING SOFTENING PROCESS :-Raw water will continue to get softened till the resin gets exhausted. Bringing back the resin to it original form is called regeneration. Softener resin is regenerated by sodium chloride- Nacl (Common salt) solution. The common salt solution is kept in the regeneration tank. During the regeneration process, salt solution is injected by the ejector tube into softener. The Nacl (salt solution) replaces ca, Mg (Hardness) from the resin, the regeneration is done every day or every few days or every week depending upon the usage and design of the water softener plant.

CHEMICAL REACTION DURING REGENERATION PROCESS :Our water softener plants are comprises of Mild Steel /SS / FRP Pressure Vessel, regeneration tank, ejector assembly, frontal piping wok with manual / Automatic multi port valve butterfly valve / conventional valves for easy operation and control. Available from 1,000 Liters/hr. to 1,00,0000 Liters / hr.

Iron is an objectionable constituent of portable water. Iron in water impart a bitter characteristic, metallic taste and cause oxidized precipitate. Coloration of water which may be yellowish brown to reddish brown and renders the water objectionable or unsuitable for use. In addition Iron stain everything with which it come in contact. Iron exists in water in two levels. One as the bi-valent, Ferrous Iron ( Fe ++) and the second one as the tri-valent, Ferric Iron (Fe+++). The Ferric Iron generally occurring in the precipitated form. Iron forms complexes of hydroxides and other in-organic complexes in solution with substantial amounts of bi-carbonate, sulphate, Phosphate, Cyanide or Halides. Presence of organic substances induces the formation of organic complexes which increase the solubility of Iron. The waters of high alkalinity have lower iron than waters of low alkalinity.

CAUSES OF IRONTo level the pH factor, chemical pre treatment is done in order to facilitate rapid aeration, than the chemical dosed water send in to the aeration tanks.

STAGE II- ONLINE AERATION TYPEChemical dosed water is send into the aeration tank consisting three chambers. The raw water is allowed to sprinkle at the first chamber through specially designed perforated pipes. The water travels from first chamber to other two chambers through accurately designed multiple vents at variable levels of the bifurcate walls, thus provides ZIG ZAG motion. When the water reaches the third chambers the dissolved iron gets oxides and become suspended iron particles.

8 HOURS STORAGE AERATION TYPEChemical dosed water is pumped in to aeration tank. The raw water is allowed to sprinkle (at the tank/sump) through specially designed perforated pipes and allowed to remain there for about 8 to 10 hrs to get oxidized through the natural process and the iron presence in the water becomes suspended iron.

STAGE III – FILTRATIONThe suspended iron water is passed through Iron removal unit, the filter media is supported on gravel bed that consists of multiple layers of progressively larger sizes of Manganese Di oxide, Activated Carbon 900 IV, Graded quartz sand, Fine sand, Super fine white sand and Pebbles, which retain the suspended iron particles. During the filtration cycle the filter bed retains the dirt and suspended iron particles from the water and accumulates within the filter bed.

BACKWASHAs the filtration progress the filter media gets loaded with the retained particles, this results in a continuous increase of pressure drop across the filter, when a predetermined pressure drop level is achieved the filter is shut down for cleaning. After backwashing the filter is rinsed with raw water and after the quality of water is achieved the filter is put back into service.

PRODUCT MODELOur iron removal plants are comprises of Mild Steel /SS / FRP Pressure Vessel, Frontal piping wok with manual / Automatic multi port valve / Butterfly valve / conventional valves for easy operation and control, Iron remove plants are available from 1000 LPH to 100000 LPH.

Activated carbon has been historically used for removal of odor, removal of color pigments from water. Further, our expertise lies in making available both Domestic and Industrial models of Activated Caron Filter, it also used as per treatment system in RO plant (ROP) and post treatment system in Waste water treatment plants (STP & ETP).

Activated Carbon filters offered by us are used for eliminating bad taste, odor as well as chlorine residue in water. This excellent filter media has carbon granules of high iodine value that helps contaminants to get adsorbed to surfaces of carbon particles

PROCESS DESCRIPTION :-The water passes through the Activated carbon filter, the filter media consist of activated granular carbon. Activated carbon adsorbs onto its surface free chlorine, organic compounds, colour and odour. The activated carbon bed is supported by a multilayer graved bed. The activated carbon bed is also backwashed at fixed intervals to dislodge any accumulated dirt particles.

BACK WASH :-As the filtration progress the filter media gets loaded with the retained particles, this results in a continuous increase of pressure drop across the filter, when a predetermined pressure drop level is achieved the filter is shut down for cleaning. The filter media is cleaned by backwash system. After backwashing the filter is rinsed with raw water and after the required quality of water is achieved the filter is put back into service. Depending on the filtered water quality required backwashing is either done with raw water or with filtered water.

PRODUCT MODEL AVAILABILITY :-Activated Carbon filter plants are comprises of Mild Steel /SS / FRP Pressure Vessel, Frontal piping wok with manual / Automatic multi port valve butterfly valve / conventional valves for easy operation and control. Available from 1,000 Liters/hr. to 1,00,0000 Liters/hr.

Multi grade filter is a depth filter that makes use of coarse and fine media mixed together in a fixed proportion. This arrangement produces a filter bed with adequate pore dimensions for retaining both large and small suspended particles. This filter performs at a substantially higher specific flow rate than conventional filters.

PROECSSRaw water passed through the Multi Grade Filter, it consists of a multi layers of filter media consisting graded sand, white sand, fine sand, activated carbon and pebbles layers, which retain the suspended particles and activated carbon adsorbs onto its surface free chlorine, organic compounds, colour and odour. During the filtration cycle the filter bed retains the dirt and suspended particles from the water and accumulates within the filter bed. As the filtration progress the filter media gets loaded with the retained particles, this results in a continuous increase of pressure drop across the filter, when a predetermined pressure drop level is achieved the filter is shut down for cleaning.

BACKWASHThe filter media is cleaned by backwash system. After back-washing the filter is rinsed with raw water and after the required quality of water is achieved the filter is put back into service. Depending on the filtered water quality required back-washing is either done with raw water or filtered water.

RANGE OF PRODUCT MODEL AVAILABILITYMulti grade Filter is comprises of Mild Steel /SS / FRP Pressure Vessel, Frontal piping wok with manual / Automatic multi port valve butterfly valve / conventional valves for easy operation and control. Available from 1,000 Liters/hr. to 1,00,0000 Liters/hr.

Mizutech India are among the prominent names in the industry occupied in offering an extensive range of Reverse Osmosis Plant. Being a quality centric firm, we assure our customers that the offered plant ensures trouble free performance and long lasting life. Our experienced professionals use only best quality raw materials and latest technology while manufacturing this plant. Besides, our provided plant can be availed within the promised time period. Features: High performance long functional life Easy to operate

We are a team of technologically adept professionals who implement revolutionary techniques for rendering high speed filtration and remarkable efficiency in the offering plants. We utilize the advanced quality membrane separation system and procure premium grade material from renowned sources to develop highly reliable RO plants. Designed to withstand the continuous duty operation in the industrial segment the offered plant can be ordered from us at the best price in the industry.

Features:| RO Capacity (LPH) | 50 LPH to 50000LPH (or design as per customer capacity requirement ) |

| Automation Grade | Semi-Automatic, Manual, Automatic |

| Max Water Recovery Rate | >75 % |

| Installation/Civil Work | Available |

| Plant Accessories | Ozonator, Chlorinator, Ultra Filtration Plant |

| Chiller Cooling Capacity (Tons) | 0.5 ton, 1 ton, 1.5 ton, 2 ton |

| Material of Construction | Stainless Steel, FRP, SS Powder coating |

| Plant Placement | Skid Mounted & on Site Construction |

Mizutech India are reckoned as major entity engaged in developing next generation 20 Liters Jar Water Filling Machine. We have conducted rigorous market research and have developed a much anticipated design for jar filling machine that is becoming the most preferred model for food processing industries. The offered model is designed and developed at our well integrated setup and trusted across the industry for its longer lifespan. Further, we are providing the highly advanced and quality tested models of jar filling machine in varied capacities

We are utilizing the next generation blow molding mechanism for these machines which are designed specially to make uniformly shaped jars featuring capacity of 20 liters. The offered model is designed under strict quality supervision and developed by procuring robust grade material from recognized vendors. Further, we are providing the quality tested machine at the best price in the marketplace.

Features:Mizutech India has attained a reputed place in the industry for providing a quality assured range of Water Filling Machine, Soda Filling Machines, Juice Filling Machines. We are offering you the complete range of 30BPM, 60BPM, 90BPM, 120BPM and also customized as per customer need and requirement. We offer these machines in varied dimensions and grades as per the demands and specifications of our respected clients. These machines are manufactured by the use of optimum quality raw material and innovative techniques at our upgraded manufacturing unit. Further, we are providing the quality tested machine at the best price in the marketplace.

Features:Mizutech India is actively instrumental in providing a superior quality collection of Fully Automatic PET Bottle Blowing Machine & Semi-automatic pet bottle machines. We manufacture the entire range from 900 BPH to 4500BPH. Mizutech India are well acclaimed as reliable firm offering highly demanded PET Bottle Blowing Machine. The offered machine is designed by keeping the operator convenience in mind. Featuring a fully automated mechanism for filling water bottle the offered model is widely installed at commercial and industrial areas for increasing the productivity. The offered machine is designed by utilizing premium grade material and high quality components and owing to our strict quality supervision we are providing the industry compliant model with assurance of reliable performance for a longer time.

Features:

WhatsApp us